FactoryLens

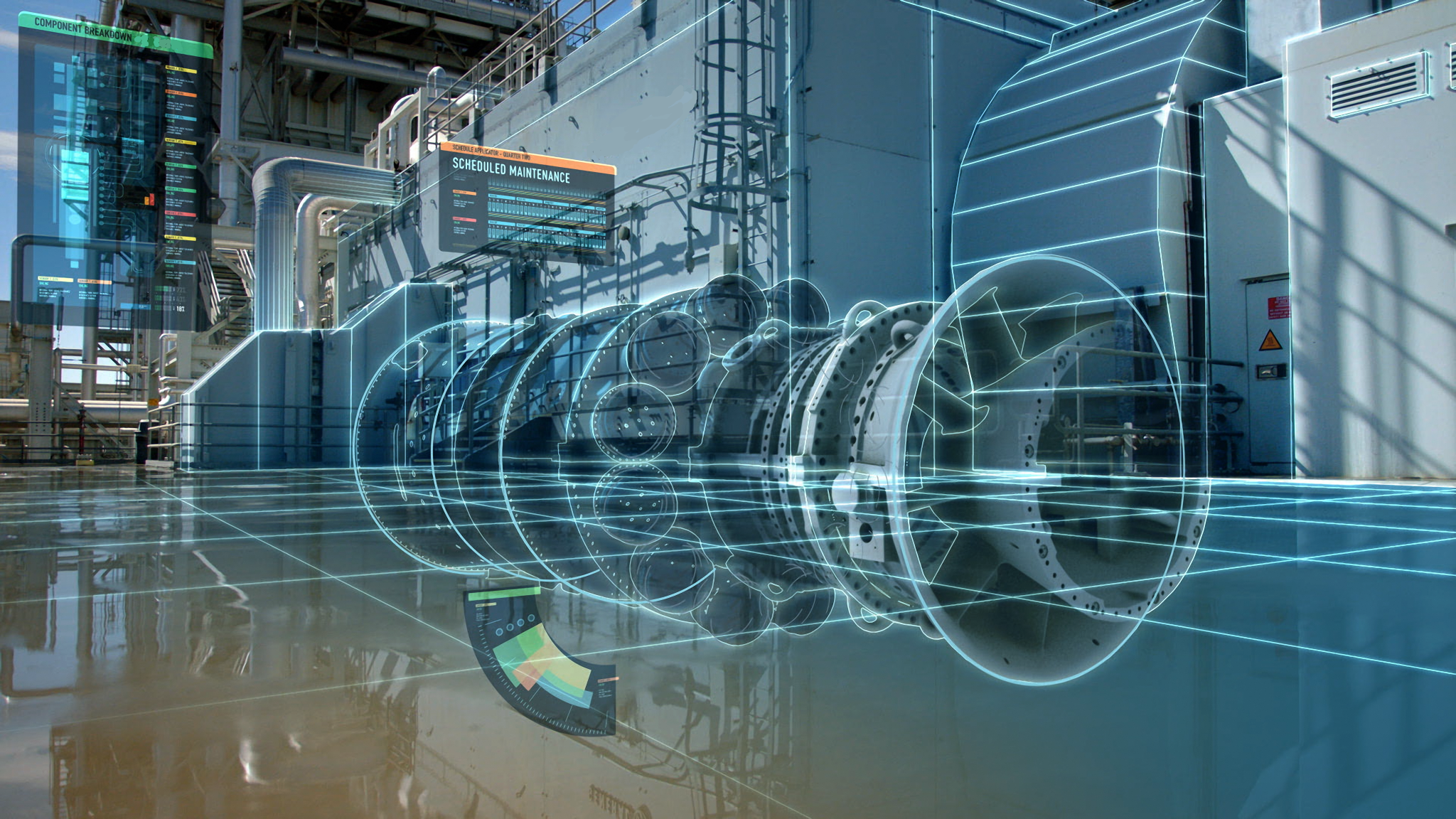

A robust platform for digital transformation of the enterprise. It converts your factory into an smart factory, where all activities are planned using AI to utilize your assets in the most optimized manner. FactoryLens is powered by our universal integrator "Augmentor" and can connect to any enterprise software. FactoryLens suite is all in one enterprise software combining the power of traditional ERP, CMMS, MIS, MES etc thereby allowing full spectrum visibility across all areas and processes of enterprise.

It allows you to be in full control of your assets. Crucial information is at your fingertips... Learn More